Since 1983, AvrAsya is a reliable partner in the petroleum industry.

AvrAsya undertakes fabrication, erection, installation and commissioning of oil & gas processing facilities...

AvrAsya is a reliable partner, offers solutions in petroleum industry.

AvrAsya is a multi-discipline contracting and service company established in 1983 with the ambitious of getting an advanced role amongst the reputable companies, depending on its capabilities, business partners and highly qualified engineering team AvrAsya is supported with qualified staff that specialist in the project management, design, engineering, procurement and construction of oil and gas projects with full implementation of quality management and HSE policies.

AvrAsya provides specialized services for the largest and most complicated demand of the dedicated projects. It undertakes fabrication, erection, installation and commissioning of oil & gas processing facilities. Also performs, as EPC Contractor, for turn-key projects.

AvrAsya aims to be one of the leading companies; integrated with all its partners, in the oil & gas industry projects in order to furnish technical and engineering services as well as meeting expectations and objectives of its clients.

AvrAsya has a deep knowledge and experience in the below mentİoned fields.

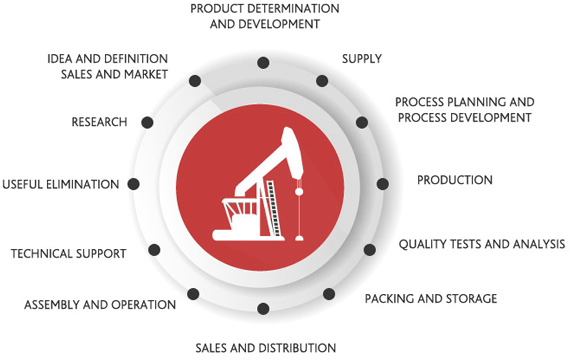

Since its early beginning AvrAsya proved to be a reliable partner in the petroleum industry. In collaboration with our partners as well as clients, AvrAsya develops innovative concepts and technologies. AvrAsya main activities include

BUT NOT LIMITED TO THE FOLLOWING:

Project management

Design, engineering, procurement and construction of oil & gas projects epc contracts on turn-key basis.

Procurement of all materials and equipment for oil and gas industry.

Fabrication, erection, installation, commissioning of oil & gas process facilities.

Supply of RO System Membranes

Supply of Filter Cartridges

Quality, health, safety and environment (QHSE) is priority for us and we are committed to achieving excellence in all activities and services we undertake. We ensure safe work practices and adherence to regulatory compliance by incorporating in all work processes an awareness to minimize losses and incident occurrences. the results achieved embark our commitment to safety.

AvrAsya’s management welcomes ideas that contribute to a safer workplace, protect the environment and improve efficiency through an integrated system of continuous improvement. we strive to create the kind of work processes that help to achieve this goal. We always consider customer’s special requirement and welcome their feedback.

Our QHSE management systems is the key to effective controls, which ensure that our activities meet the expectations of our clients and conform to all regulatory and legal requirements.

Dedicated to the pursuit of excellence in project execution and product quality, we take a proactive and scientific approach to drive continuous improvement throughout our organization. Experienced project team ensures that AvrAsya strictly conform to client specifications, budgets and delivery schedules without compromising on quality, safety or environment standards.

We have successfully completed many projects, maintaining an overall excellent safety rating. This success has allowed us to develop lasting relationships and secure continuous business with our clients.

Key onshore references include; Khurmala Dome Project, where AvrAsya has been involved from the pre-engineering of CPS1 in 2004 through the first EPC contract and several studies continuously implemented until today; and BTC Project, focusing on the construction of 8500 m3 underground steel tank enveloped by a reinforced concrete containment including piping systems interconnection on a pile foundation in Georgia.

AvrAsya aims to be one of the leading companies integrated with all of its partners, in the Oil & Gas industry project thus to provide technical and engineering services as well as meeting expectations and objectives of the clients.

| DESCRIPTION OF PROJECT | COMPLETION DATE |

| Fabrication and supply of 24’’x28” Pig Receivers and Launchers For Crude Oil Pipeline | 2013 |

| Procurement and Supply of Pipe, Fitting & Valves for Gas Treatment Plant | 2013 |

| Supply of Commissioning Spare Parts for Kashagan Field Project | 2011-2013 |

| Fabrication and supply of 20”x24” Pig Receivers & Launchers for Crude Oil and 24’’x28” and 36’’x40’’ Pig Receivers & Launchers Natural Gas Pipelines | 2012 |

| Fabrication and supply of 4 pcs 20”x24” Pig Launcher & Recievers for Khurmala Pipeline | 2012 |

| Supply and lining of membrane for Evaporation Pond of Erbil Refinery | 2012 |

| Supply and lining of membrane for Evaporation Pond of Khurmala Central Process Station | 2012 |

| Procurement and suply of Materials for Prover Meters | 2012 |

| Procurement and supply of Pipes , Fittings & Valves of Gas Treatment Plant. | 2012 |

| Procurement and Supply of Oil tanks | 2012 |

| Fabrication and Supply of Inlet manifolds for Oil Field | 2011 |

| Fabrication and Supply of 1st & 2nd stage separators and gas scrubbers | 2010 |

| Procurement and Supply of Lapmaster and spare parts | 2010 |

| Btc 8500m3 undergroud oil tank and pipeline | 2007 |

| Fabrication and supply of Six (6) Production Separators and Three (3) Test Separators For the Khurmala Dome Project | 2006 |

| MANIPULATORS FOR LPG CYLINDERS (Taji, Iraq) | 2003 |

| LPG STORAGE & FILLING PLANT (capacity 520 cylinders/hour) (Erbil, Iraq) | 2002 |

| STEEL STRUCTURES Dubai | 2002 |

| PRESSURE TANKS for the North Refineries Company in Baiji Dubai | 2002 |

| TUBE BUNDLES HEAT EXCHANGER for the North Refineries Company in Baiji Dubai | 2002 |

| CERAMIC BALLS (Kirkuk, Iraq) | 2002 |

| SRU CATALYST (Kirkuk, Iraq) | 2002 |

| MOLECULAR SIEVE CATALYST (Kirkuk, Iraq) | 2002 |

| CHEMICAL MATERIALS (Kirkuk, Iraq) | 2002 |

| BARIT FOR DRILLING (Kirkuk, Iraq) | 2002 |

| STEEL PLATES FOR STORAGE TANKS (Kirkuk, Iraq) | 2002 |

| AEROSOL FILLING MACHINE (Taji, Iraq) | 2002 |

| MIC MAC WELDING MACHINE (Taji, Iraq) | 2002 |

| WELDING MACHINES FOR LPG CYLINDERS (Taji, Iraq) | 2002 |

| GAS SENSORS & ALARM SYSTEM for TAJI PLANT (Taji, Iraq) | 2002 |

| EX-PROOF LIGHTING EQUIPMENT (Baiji, Iraq) | 2002 |

| MAINTENANCE & UPGRADING DRUM PRODUCTION & FILLING PLANT (Baiji, Iraq) | 2002 |

| MODIFICATION OF EXISTING LUBE OIL FILLING UNIT (Baiji, Iraq) | 2002 |

| 5 lt PLASTIC CONTAINERS MOULD (Baiji, Iraq) | 2002 |

| LPG STORAGE & FULLY AUTOMATIC FILLING PLANT (capacity 1,200 cylinder/hour) N.CYPRUS | 2001 |

| DRUMS MAINTENANCE (Baiji, Iraq) | 2001 |

| INSTRUMENT SUPPLY (Baiji, Iraq) | 2001 |

| TRANSMITTERS (Baiji, Iraq) | 2001 |

| TANK MIXERS (Baiji, Iraq) | 2001 |

| SPARE PARTS FOR LIGHTING (Baiji, Iraq) | 2001 |

| VISCOSITY INDEX IMPROVER (Baiji, Iraq) | 2001 |

| FIRE ALARM SYSTEM (Baiji, Iraq) | 2001 |

| EL. WEIGHING BRIDGE (Taji, Iraq) | 2001 |

| LPG CYLINDERS REPAIR And MAINTENANCE PLANT (Taji, Iraq) | 2001 |

| LPG STORAGE & FULLY AUTOMATIC FILLING PLANT (capacity 1,200 cylinder/hour) (Dohuk, Iraq) | 2001 |

| GEOMEMBRANE (Baghdad, Iraq) | 2001 |

| COMMUNICATION CABLES (Baghdad, Iraq) | 2001 |

| BLENDING, PACKING AND FILLING PLANT (NIZIP, GAZIANTEP, TURKEY) | 2000 |

| TANK GAUGING AND CONTROL SYSTEM (Baku, Azerbaijan) | 2000 |

| MISCALLANEOUS TOOLS, MACHINES AND EQUIPMENT FOR REPAIR OF LPG CYLINDERS (WELDING MACHINES) (Taji, Iraq) | 2000 |

| TELESCOPIC CONVEYER & VALVE SCREWING MACHINE (Taji, Iraq) | 2000 |

| 50.000 MTON CAPACITY ATOIL LUBE OIL BLENDING AND PACKAGING COMPLEX CONSTRUCTION (Baku, Azerbaijan) | 1999 |

| ACCESS CONTROL SYSTEM (Baku, Azerbaijan) | 1999 |

| PHASE II - NATURAL GAS DISTRIBUTION STATIONS (Bursa, Turkey) | 1999 |

| SUPPLY AND ERECTION OF DRUM FILLING AND PLASTIC BOTTLE PRODUCTION LINE Ufa, Bashkortostan, Russia | 1999 |

| NATURAL GAS NETWORK (Eskishehir, Turkey) | 1998 |

| HEATER REVAMP (Izmit, Türkiye) | 1998 |

| FCC, FLUID CATALYTIC CRACKING SYSTEM (Baku, Azerbaijan) | 1998 |

| SCAN 3000 (Baku, Azerbaijan) | 1998 |

| FIRE ALARM, SECURTY AND ACCESS CONTROL SYSTEM (Baku, Azerbaijan) | 1998 |

| BUILDING AUTOMATION AND ACCESS CONTROL SYSTEM (Baku, Azerbaijan) | 1998 |

| FLOATING DRUMS (Iskenderun, Turkey) | 1998 |

| LABORATORY EQUIPMENT (Baku, Azerbaijan) | 1997 |

| FIELD PIPELINE AND ABOVE GROUND FUEL TANKS (Adiyaman, Turkey) | 1997 |

| TERMINAL CRUDE OIL TANKS AND FIRE EXTINGUISHING SYSTEM (Batman, Türkiye) | 1997 |

| SUB-SEA PIPELINES (Istanbul, Turkiye) | 1997 |

| BULK (TRUCK) LOADING PLATFORM AND DRUM FILLING UNITS Ufa, Bashkortostan, Russia | 1997 |

| SECURITY AND ACCESS CONTROL + CCTV SYSTEM (Baku, Azerbaijan) | 1997 |

| FIRE ALARM, SECURTY AND BUILDING AUTOMATION (Baku, Azerbaijan) | 1997 |

| CRUDE DESTILLATION UNIT REHABILITATION (Istanbul, Türkiye) | 1996 |

| OXYGEN GENERATION PLANT (Eregli, Türkiye) | 1996 |

| FLOWMETERS - PETROLEUM PRODUCT BULK FILL IN PORT (Baku, Azerbaijan) | 1996 |

| EQUIPMENT SUPPLY (THERMOMETERS, CONTROL SYSTEM PARTS, CONTROL VALVES) (Baku, Azerbaijan) | 1996 |

| LABORATORY EQUIPMENT FOR PETROLEUM PRODUCTS AND LUBRICANTS (Baku, Azerbaijan) | 1996 |

| COMPUTER SOFTWARE AND HARDWARE (Baku, Azerbaijan) | 1996 |

| SECURITY AND ACCESS CONTROL SYSTEMS (Baku, Azerbaijan) | 1996 |

| LPG STORAGE & FULLY AUTOMATIC FILLING PLANT (capacity 1,200 cylinder/hour) Baku, Yevlakh, Ganja, Azerbaijan | 1996 |

| FIRE ALARM SYSTEM (Baku, Azerbaijan) | 1996 |

| SETTING INTO MOTION AUTOMATICLUBE OILS PACKING LINE Ufa, Bashkortostan, Russia | 1996 |

| DEMIRALIZATION PLANT (Batman, Türkiye) | 1995 |

| MICRO TDC-3000 FOR CRUDE OIL UNIT 202 IN THE REFINERY (Baku, Azerbaijan) | 1994 |

| PLANT EXPANSION FEASIBILITY STUDY (Batman, Türkiye) | 1994 |

| VACUUM / CRUDE UNIT, capacity 40,000 bpd (Baku, Azerbaijan) | 1993 |

| TDC-3000 FOR CRUDE OIL UNIT NO.305 IN THE REFINERY (Baku, Azerbaijan) | 1993 |

| AKTYUBINSK PETROL REFINERY (Aktyubinsk, Kazakhstan) | 1992 |

| ELF LUBE OIL BLENDING AND PACKING PLANT (Menemen, Izmir) | 1990 |

AVRASYA TEKNOLOJİ MÜHENDİSLİK VE İNŞAAT ANONİM ŞİRKETİ KİŞİSEL VERİLERİN İŞLENMESİ VE KORUNMASI POLİTİKASI

1 – POLİTİKANIN AMACI

AVRASYA TEKNOLOJİ MÜHENDİSLİK VE İNŞAAT ANONİM ŞİRKETİ (“AVRASYA” veya “ŞİRKET”), kişisel verilerin korunmasına ilişkin Türkiye Cumhuriyeti Anayasası, 6698 sayılı Kişisel Verilerin Korunması Kanunu (“KVKK”) ve sair mevzuat tarafından getirilmiş yasal düzenlemelere uymayı ve AVRASYA tarafından verileri işlenen bireylerin hak ve özgürlüklerini korumayı taahhüt etmektedir. Bu amaçla Veri Sorumlusu olarak; Şirketimiz tarafından yürütülen kişisel veri işleme faaliyeti ve kişisel verilerin korunmasına yönelik süreçler hakkında açıklamalarda bulunmak, uygulamada şeffaflığı ve hukuka uygunluğu sağlamak, kişisel verileri Şirketimiz tarafından işlenen veri sahibi gerçek kişileri bilgilendirmek ve yeni yasal düzenlemeler doğrultusunda geliştirilmek üzere işbu Kişisel Verilerin İşlenmesi ve Korunması Politikası (‘Politika’) hazırlanmıştır.

Kişisel Verilerin Korunması hakkı, Türkiye Cumhuriyeti Anayasası MADDE 20’de aşağıdaki şekilde yer almaktadır.

“Herkes, özel hayatına ve aile hayatına saygı gösterilmesini isteme hakkına sahiptir. Özel hayatın ve aile hayatının gizliliğine dokunulamaz (Ek fıkra: 12/9/2010-5982/2 md.). Herkes, kendisiyle ilgili kişisel verilerin korunmasını isteme hakkına sahiptir. Bu hak; kişinin kendisiyle ilgili kişisel veriler hakkında bilgilendirilme, bu verilere erişme, bunların düzeltilmesini veya silinmesini talep etme ve amaçları doğrultusunda kullanılıp kullanılmadığını öğrenmeyi de kapsar. Kişisel veriler, ancak kanunda öngörülen hallerde veya kişinin açık rızasıyla işlenebilir. Kişisel verilerin korunmasına ilişkin esas ve usuller kanunla düzenlenir.”

Bireyin temel hak ve özgürlüklerini kişisel verilerin işlenmesi sırasında korumayı amaçlayan, 6698 sayılı Kişisel Verilerin Korunması Kanunu, önceki metinler üzerinde yapılan çeşitli değişikliklerle 18 Ocak 2016 tarihinde TBMM Başkanlığı’na sevk edilmiş ve 24 Mart 2016 tarihinde TBMM Genel Kurulu tarafından kabul edilerek kanunlaşmış, 7 Nisan 2016 tarih ve 29677 sayılı Resmi Gazete’de yayımlanarak yürürlüğe girmiştir.

6698 sayılı Kişisel Verilerin Korunması Kanununun (Kanun) 12.nci maddesinin (1) numaralı fıkrasında Veri Sorumlusunun;

- Kişisel verilerin hukuka aykırı olarak işlenmesini önlemek,

- Kişisel verilere hukuka aykırı olarak erişilmesini önlemek,

- Kişisel verilerin muhafazasını sağlamak,

amacıyla uygun güvenlik düzeyini temin etmeye yönelik gerekli her türlü teknik ve idari tedbirleri almak zorunda olduğu, (5) numaralı fıkrasında ise, işlenen kişisel verilerin kanuni olmayan yollarla başkaları tarafından elde edilmesi hâlinde, veri sorumlusunun bu durumu en kısa sürede ilgilisine ve Kişisel Verileri Koruma Kuruluna (“Kurul”) bildireceği, Kurulun, gerekmesi hâlinde bu durumu, kendi internet sitesinde ya da uygun göreceği başka bir yöntemle ilan edebileceği hükme bağlanmıştır.

6698 sayılı KVKK kapsamında, Veri Sorumlusu olarak; Şirketimiz tarafından yürütülen kişisel veri işleme faaliyeti ve kişisel verilerin korunmasına yönelik süreçler hakkında açıklamalarda bulunmak, uygulamada şeffaflığı ve hukuka uygunluğu sağlamak ve kişisel verileri birlik tarafından işlenen veri sahibi gerçek kişileri bilgilendirmek amacıyla bu Politika hazırlanmıştır.

Bu Politika ile Ortak/Hissedar, Potansiyel Ürün ve/veya Hizmet Alıcıları Çalışanları, Ürün ve/veya Hizmet Alıcıları Çalışanları, Tedarikçi Çalışanı/Yetkilisi, Ziyaretçi, sözleşmeye dayalı çalışma yapılan Müşavirler, Hukuk Danışmanlarının, sözleşme ve iş ilişkisi kapsamında kişisel verileri işlenen diğer üçüncü şahısların kişisel verilerinin hukuka uygun şekilde korunması ve işlenmesi prensipleri oluşturulmaktadır.

Şirket bu Politika ile bir Anayasal hak olan Kişisel Verilerinin Korunmasını bir Şirket Politikası haline getirmekte ve hukuki ve sosyal sorumluluğu kapsamında Kişisel Veri Koruma Kanunu ve mevzuat ve düzenlemelerine uymayı taahhüt etmektedir. KVK Politikası ile Şirket bünyesinde kişisel verilerin hukuka uygun olarak işlenmesi ve korunması konusunda farkındalığın oluşması ve tüm süreçlerde mevzuata uyumu temin etmek için sürdürülebilir ve denetlenebilir sistemin kurulması amaçlanmaktadır.

Kişisel Verilerin Korunması Kanunu ve ek mevzuatların uygulanmasına yönelik olarak Şirket içerisinde gerekli politika ve prosedürler düzenlenmekte, aydınlatma metinleri oluşturulmakta, açık rızalar uygulanmakta, gizlilik sözleşmeleri yapılmakta, görev tanımları revize edilmekte, kişisel verilerin korunması için Şirketimiz tarafından mevzuata uygun idari ve teknik güvenlik tedbirleri alınmakta, bu kapsamda gerekli denetimler yapılmakta veya yaptırılmaktadır.

2- TANIMLAR

Kişisel Verileri Koruma Kanunu ve Şirketin Kişisel Verilerin Korunması ve İşlenmesi Politikasında yer alan bazı tanımların açıklamalarına aşağıda yer verilmiştir.

Kişisel Verilerin İşlenmesi: Kişisel verilerin tamamen veya kısmen otomatik olan ya da herhangi bir veri kayıt sisteminin parçası olmak kaydıyla otomatik olmayan yollarla elde edilmesi, kaydedilmesi, depolanması, muhafaza edilmesi, değiştirilmesi, yeniden düzenlenmesi, açıklanması, aktarılması, devralınması, elde edilebilir hâle getirilmesi, sınıflandırılması ya da kullanılmasının engellenmesi gibi veriler üzerinde gerçekleştirilen her türlü işlem.

Kişisel Veri Sahibi: Kişisel verisi işlenen Ortak/Hissedar, Potansiyel Ürün ve/veya Hizmet Alıcıları Çalışanları, Ürün ve/veya Hizmet Alıcıları Çalışanları, Tedarikçi Çalışanı/Yetkilisi, Ziyaretçi, sözleşmeye dayalı çalışma yapılan Müşavirler, Hukuk Danışmanlarının, sözleşme ve iş ilişkisi kapsamında kişisel verileri işlenen diğer üçüncü şahıslar.

Kişisel Veri: Kimliği belirli veya belirlenebilir gerçek kişiye ilişkin her türlü bilgi.

Örneğin; adı-soyadı, TCKN, e-posta, adres, iş adresi, doğum tarihi, doğum yeri, kredi kartı numarası, ehliyet no, banka hesap numarası, pasaport no, ruhsat no, diploma vb.

Özel Nitelikli Kişisel Veri: Irk, etnik köken, siyasi düşünce, felsefi inanç, din, mezhep veya diğer inançlar, kılık kıyafet, dernek vakıf ya da sendika üyeliği, sağlık, cinsel hayat, ceza mahkumiyeti ve güvenlik tedbirleriyle ilgili veriler ile biyometrik ve genetik veriler özel nitelikli verilerdir.

Veri Sorumlusu: Kişisel verilerin işlenme amaçlarını ve vasıtalarını belirleyen, verilerin sistematik bir şekilde işlendiği ve saklandığı veri kayıt sistemini kuran ve yöneten kişi veri sorumlusudur.

Veri İşleyen: Veri sorumlusunun verdiği yetki kapsamında onun adına veri işleyen gerçek veya tüzel kişi.

Açık Rıza: Belirli bir konuya ilişkin, bilgilendirilmeye dayanan ve özgür iradeyle açıklanan rıza.

Kişisel Verilerin Silinmesi: Kişisel verilerin ilgili kullanıcılar için hiçbir şekilde erişilmez ve tekrar kullanılamaz hale getirilmesi işlemidir.

Kişisel Verilerin Yok edilmesi: Kişisel verilerin hiç kimse tarafından hiçbir şekilde erişilemez, geri getirilemez ve tekrar kullanılamaz hale getirilmesi işlemidir

Anonim Hale Getirme: Kişisel verilerin başka verilerle eşleştirilse dahi hiçbir surette kimliği belirli veya belirlenebilir bir gerçek kişiyle ilişkilendirilemez hale getirilmesidir.

KVKK: 7 Nisan 2016 tarih ve 29677 sayılı Resmi Gazete de yayımlanan Kişisel Verilerin Korunması Kanunu

KVK Kurulu: Kişisel Verileri Koruma Kurulu

Kişisel Veri Saklama ve İmha Politikası: Kişisel Verilerin Silinmesi, Yok Edilmesi, Anonim Hale Getirilmesi Hakkında Yönetmelik gereğince, Şirket tarafından kişisel verilerin işlendikleri amaç için gerekli olan azami süreyi belirleme işlemi ile silme, yok etme ve anonim hale getirme işlemi için dayanak yapılmış olan Şirket “Kişisel Veri Saklama ve İmha Politikası”.

Veri Sorumluları Sicili: KVK Kurulu gözetiminde, Kişisel Verileri Koruma Kurumu Başkanlığı gözetiminde tutulan ve kamuya açık olan Veri Sorumluları Sicili.

Veri Sorumlusuna Başvuru Usul ve Esasları Hakkında Tebliğ: 10 Mart 2018 tarihli ve 30356 sayılı Resmî Gazete’de yayımlanarak yürürlüğe giren Veri Sorumlusuna Başvuru Usul ve Esasları Hakkında Tebliğ.

2- KİŞİSEL VERİLERİN İŞLENMESİNE VE KORUNMASINA İLİŞKİN GENEL İLKELER

2.1. Kişisel verilerin korunması ve işlenmesinde KVKK ile bu kanuna bağlı çıkartılan diğer yasal düzenlemelerde belirtilen hükümler esas alınır.

2.2. Bu Politika ile Ortak/Hissedar, Potansiyel Ürün ve/veya Hizmet Alıcıları Çalışanları, Ürün ve/veya Hizmet Alıcıları Çalışanları, Tedarikçi Çalışanı/Yetkilisi, Ziyaretçi, sözleşmeye dayalı çalışma yapılan Müşavirler, Hukuk Danışmanlarının, sözleşme ve iş ilişkisi kapsamında kişisel verileri işlenen diğer üçüncü şahısların kişisel verilerinin hukuka uygun şekilde korunması ve işlenmesi ile özel nitelikli kişisel verilerinin, mevzuat kapsamında belirtilen esaslar dahilinde Şirketimiz tarafından işlenmesi ve korunmasının prensipleri oluşturulmaktadır.

2.3. Kişisel veriler, Veri Sahibinin açık rızası olmadan işlenemez, başka bir kişiye/sisteme aktarılamaz, kullanılamaz ve sunulamaz. Kişinin açık rızası; açık, bilgilendirmeye ve özgür iradeye dayalı bir biçimde alınmaktadır.

2.4. Kişisel veriler, Şirketin belirlemiş olduğu bölüm ve sistemlerde saklanır. Kişisel verilerin işlenmesi, verilere erişim ve bu verilerin kullanımı sadece Kişisel Veri Koruma Sorumlusu tarafından yetkilendirilmiş kişilerce yapılır.

2.5. Kişisel verilerin korunması anayasal bir hak olup, Şirketimizin öncelikleri arasında yer almaktadır. Bu amaçla; kişisel verilerin korunması süreçlerinin yönetimi, gelişmelerin takibi ve analizi amacıyla Şirket bünyesinde “Kişisel Veri Koruma Görevlisi” atanmıştır.

2.6. İşbu Politikada belirtilen hususların uygulanmasına yönelik Şirket bünyesinde gerekli prosedürler oluşturulmuş, aydınlatma metinleri düzenlenmiş, gizlilik sözleşmeleri yapılmış, görev tanımları revize edilmiş, kişisel verilerin korunması için gerekli idari ve teknik tedbirlerin tamamı alınmıştır.

2.7. Tüm Şirket çalışanları, kişisel verilerin korunması ve güvenliğinden bizzat sorumludur. KVKK ile buna bağlı diğer yasal düzenlemelere ve işbu Politikaya uyum konusunda periyodik olarak denetim yapılır.

2.8. Şirket tarafından düzenlenerek yayınlandığı tarihte yürürlüğe giren işbu Politika, Şirket’in internet sitesinde yayımlanır ve Kişisel Veri Sahiplerinin talebi üzerine ilgili kişilerin erişimine sunulur. Şirket, yasal düzenlemelere paralel olarak Politika’da değişiklik yapma hakkını saklı tutar. Politika’nın güncel versiyonuna Şirket web sitesinden erişilebilir.

2.9. İşbu politikada belirtilen esaslara ve yasal mevzuata aykırı olarak kişisel verileri kaydeden, paylaşan ve/veya gerektiğinde silmeyen kişilere Türk Ceza Kanunu’nun (TCK) 135-140. maddelerinde belirtilen yaptırımlar uygulanır.

3. KİŞİSEL VERİLERİN İŞLENMESİNE İLİŞKİN GENEL İLKELER

Şirket tarafından Kişisel Veriler, Kanunda ve bu Politikada öngörülen usul ve esaslara uygun olarak işlenir. Şirket, Kişisel Verileri işlerken, KVKK madde 4 kapsamında, aşağıdaki ilkelerle hareket eder:

Kişisel verilerin hukuka ve dürüstlük kurallarına uygun olarak işlenmesi: Şirket, kişisel verilerinizin işlenmesinde kanunlara, ikincil düzenlemelere ve hukukun genel ilkelerine uygun olarak hareket eder; kişisel verileri işlenme amacı ile sınırlı olarak işlemeye ve veri sahiplerinin makul beklentilerini dikkate almaya önem verir.

Kişisel verilerin doğru ve güncel olması: Şirket tarafından işlenen kişisel verilerinizin güncel olup olmadığına, buna ilişkin kontrollerin yapılmasına dikkat edilir. Veri sahiplerine bu kapsamda doğru ve güncel olmayan verilerinin düzeltilmesini veya silinmesini isteme hakkı tanınır.

Kişisel verilerin belirli, açık ve meşru amaçlar için işlenmesi: Şirket, her bir kişisel veri işleme faaliyetinden önce veri işleme amaçlarını tespit eder ve bu amaçların hukuka aykırı olmamasına dikkat eder.

Kişisel verilerin işlendiği amaçla bağlantılı, sınırlı ve ölçülü olması: Şirket tarafından veri işleme faaliyeti toplama amacını gerçekleştirme için gerekli olan kişisel verilerle sınırlandırılmakta ve bu amaçla ilişkili olmayan kişisel verilerin işlenmemesi için gerekli adımlar atılmaktadır.

Kişisel verilerin mevzuatın ya da işleme amaçlarının gerektirdiği süre kadar saklanması: Şirket tarafından kişisel veri işleme amacının ortadan kalkmasından sonra ya da mevzuatta öngörülen sürenin dolması ile kişisel veriler silinmekte, yok edilmekte veya anonimleştirilmektedir.

4. KİŞİSEL VERİLERİN İŞLENMESİNE YÖNELİK HUSUSLAR

4.1-KİŞİSEL VERİLERİN İŞLENME ŞARTLARI:

Kişisel veriler, Kanun’un 5. ve 6. maddelerinde belirtilen kişisel veri işleme şartları kapsamında işlenir. Bahsi geçen amaçlarla gerçekleştirilen işleme faaliyetinin, Kanun kapsamında öngörülen şartlardan herhangi birini karşılamıyor olması halinde, ilgili işleme sürecine ilişkin olarak Şirket tarafından açık rıza temin edilmektedir. Kanunun 5. maddesinin 1. fıkrasında yer alan “Kişisel veriler ilgili kişinin açık rızası olmaksızın işlenemez” düzenlemesi çerçevesinde, Şirketimiz Kanunun tanıdığı istisnai haller dışında, açık rızanın bulunması halinde kişisel veri işlemektedir.

KVKK m.5 uyarınca aşağıda belirtilen şartlardan birinin varlığı halinde, ilgili kişinin açık rızası aranmaksızın kişisel veriler işlenebilir:

- Kanunlarda açıkça öngörülmesi: Veri sahibinin kişisel verileri, kanunda kişisel verilerin işlenmesine ilişkin açıkça bir hüküm olması halinde işbu veri işleme şartının varlığından söz edilebilecektir.

- Fiili imkansızlık nedeniyle ilgilinin açık rızasının alınamaması: Fiili imkansızlık nedeniyle ilgilinin açık rızasını açıklayamayacak durumda bulunan veya rızasına hukuki geçerlilik tanınmayan kişinin kendisinin ya da bir başkasının hayatı veya beden bütünlüğünün korunması için zorunlu olması halinde veri sahibinin kişisel verileri işlenebilecektir.

- Bir sözleşmenin kurulması veya ifasıyla doğrudan doğruya ilgili olması: Veri sahibinin taraf olduğu bir sözleşmenin kurulması veya ifasıyla doğrudan doğruya ilgili olması kaydıyla, kişisel verilerin işlenmesinin gerekli olması halinde işbu şart yerine getirilmiş sayılacaktır.

- Şirketin hukuki yükümlülüğünü yerine getirmesi: Kişisel veri işlemenin, veri sorumlusu olan Şirketin hukuki yükümlülüğünü yerine getirebilmesi için zorunlu olması halinde kişisel veri işlenebilecektir.

- Kişisel verinin, ilgili kişi tarafından alenileştirilmiş olması: Veri sahibinin, kişisel verisini alenileştirmiş olması halinde ilgili kişisel veriler alenileştirme amacıyla sınırlı olarak işlenebilecektir.

- Bir hakkın tesisi, kullanılması veya korunması için veri işlemenin zorunlu olması: Bir hakkın tesisi, kullanılması veya korunması için veri işlemenin zorunlu olması halinde veri sahibinin kişisel verileri işlenebilecektir.

- Şirketin meşru menfaatleri için veri işlenmesinin zorunlu olması: Kişisel Veri Sahibinin temel hak ve özgürlüklerine zarar vermemek kaydıyla, Şirketin meşru menfaatleri için veri işlenmesinin zorunlu olması halinde veri sahibinin kişisel verileri işlenebilecektir.

4.2-ÖZEL NİTELİKLİ KİŞİSEL VERİLERİN İŞLENME ŞARTLARI

Özel nitelikli kişisel veriler Şirket tarafından, işbu Politika’da belirtilen ilkelere uygun olarak gerekli her türlü idari ve teknik tedbirler alınarak ve aşağıdaki şartların varlığı halinde işlenmektedir. Özel nitelikteki verilerin işlenebilmesi için aşağıda Kanunun 6. maddesinde de yer verilen istisnalar dışında veri sahibinin açık rızasının alınması zorunludur.

Kişisel veri sahibinin sağlık ve cinsel hayat dışındaki özel nitelikli kişisel verileri: Kanunda kişisel verilerin işlenmesine ilişkin açıkça bir hüküm olması halinde veri sahibinin açık rızası aranmaksızın işlenebilecektir.

Kişisel veri sahibinin sağlığına ve cinsel hayatına ilişkin özel nitelikli kişisel veriler: Kamu sağlığının korunması, koruyucu hekimlik, tıbbi teşhis, tedavi ve bakım hizmetlerinin yürütülmesi, sağlık hizmetleri ile finansmanının planlanması ve yönetimi şeklinde olup; sır saklama yükümlülüğü altında bulunan kişiler veya yetkili kurum ve kuruluşlar tarafından açık rıza almadan” işlenebilmektedir. Aksi durumda söz konusu özel nitelikli kişisel verilerin işlenebilmesi için veri sahibinin açık rızası alınacaktır.

5. KİŞİSEL VERİLERİN KORUNMASINA YÖNELİK HUSUSLAR

Şirketimiz, Kanun’un 12. maddesine uygun olarak, kişisel verilerin hukuka aykırı olarak açıklanmasını, erişimini, aktarılmasını veya başka şekillerde meydana gelebilecek güvenlik eksikliklerini önlemek için, korunacak verinin niteliğine göre gerekli tüm idari ve teknik tedbirlerini almaktadır. İdari ve teknik tedbirlere, işbu Protokol’ün “Kişisel Verilerin Gizliliği ve Güvenliğinin Sağlanması” başlıklı 13. Maddesinde ayrıntılı olarak yer verilmiştir.

Özel Nitelikli Kişisel Verilerin Korunması

Şirketimiz için KVKK kapsamında “Özel Nitelikli” olarak belirlenen ve hukuka uygun olarak işlenen özel nitelikli kişisel verilerin korunması özel öneme sahiptir. KVKK’nın 6.maddesinde, hukuka aykırı olarak işlendiğinde kişilerin mağduriyetine veya ayrımcılığa sebep olma riski taşıyan bir takım kişisel veri “özel nitelikli” olarak belirlenmiş olup bu verilerin işlenmesinde dikkat ve hassasiyet gösterilmesi gerekmektedir.

KVKK ile birtakım kişisel verilere, hukuka aykırı olarak işlendiğinde kişilerin mağduriyetine veya ayrımcılığa sebep olma riski nedeniyle özel önem atfedilmiştir. Bu veriler; ‘ırk, etnik köken, siyasi düşünce, felsefi inanç, din, mezhep veya diğer inançlar, kılık ve kıyafet, dernek, vakıf ya da sendika üyeliği, sağlık, cinsel hayat, ceza mahkûmiyeti ve güvenlik tedbirleriyle ilgili veriler ile biyometrik ve genetik’ verilerdir.

Şirketimiz tarafından, KVKK ile “özel nitelikli” olarak belirlenen ve hukuka uygun olarak işlenen özel nitelikli kişisel verilerin korunmasında hassasiyetle davranılmaktadır. Bu kapsamda, Şirket tarafından, kişisel verilerin korunması için alınan teknik ve idari tedbirler, özel nitelikli kişisel veriler bakımından özenle ve özel olarak uygulanmaktadır.

Özel Nitelikli Veri kapsamında, Şirket bünyesinde adli sicil belgesi ve kan grubu, sağlık raporları gibi sağlık bilgilerini içeren belgeler özlük dosyalarında bulunmaktadır. Bu özel nitelikli kişisel verilere erişebilen kişilere periyodik gizlilik eğitimleri verilmekte, erişim yetkisi kapsam ve süreleri belirlenmekte ve periyodik olarak denetimler yapılmakta ve gizlilik sözleşmeleri imzalanmaktadır. İlgili kişinin Şirketimiz ile ilişiğinin/sözleşmesel ilişkisinin kalmaması halinde erişim yetkisi derhal iptal edilmektedir.

Bu şekilde fiziki olarak saklanan kişisel sağlık verilerinin bulunduğu fiziki dosyalar kilitli ve sadece görevlendirilen yetkili kişinin ve bu dosyaları muhafaza ile görevlendirilen kişilerin erişebildiği alanlarda saklanmaktadır.

6. ŞİRKET TARAFINDAN İŞLENEN KİŞİSEL VERİLERİN KATEGORİZASYONU VE İŞLENME AMAÇLARI

6.1-Kişisel Veri Kategorileri ve Açıklamaları:

Şirket tarafından KVKK ve işbu Politikada belirtilen amaçlar ve şartlar çerçevesinde işlenen kişisel veri kategorileri ile kategorilerin açıklamalarına aşağıda yer verilmektedir;

Kimlik Verisi | Ad, soyadı, doğum tarihi, doğduğu ülke, doğduğu şehir, cinsiyet, medeni durumu, milliyeti, TC kimlik kartı üzerindeki bilgileri (TCKN, seri no, cüzdan numarası ile sıra no, cilt no, kayıt no, nüfusa kayıtlı olunan il/ilçe/köy/mahalle, verildiği yer, veriliş sebebi, veriliş tarihi), vergi numarası, SGK numarası, imza bilgisi, fotoğraf, ehliyet, pasaport, yabancı kimlik no vb. bilgiler. |

İletişim Verisi | Adres bilgisi, telefon numarası, e-posta adresi, cep telefonu numarası, kurumsal e-posta adresi, kep adresi, şirket içi iletişim bilgileri, dahili telefon numarası vb. bilgiler. |

Lokasyon Verisi | Bulunduğu konum verisi (araç takip sistemi) |

Müşteri İşlem | Fatura düzenlenebilmesi amacıyla kimlik ve fatura bilgileri, sipariş formu, yazılı teklifler, sözleşmeler, e-mailler vb. bilgiler. |

Hukuki İşlem | Haciz ihbarnamesi, adli makamlarla yazışmalar, dava ve icra takip dosyalarına ilişkin dosya ve borç bilgileri, Vekaletname, hukuki alacak ve haklarının tespiti, takibi ve borçlarının ifası ile kanuni yükümlülükler kapsamında işlenen veriler. |

Özel Nitelikli Kişisel Veri | KVK Kanunu’nun 6. maddesinde belirtilen veriler (kan grubu da dahil hissedar/ortak sağlık verileri) |

Finans | Her türlü finansal sonucu gösteren bilgi, belge ve kayıtlara ilişkin işlenen kişisel veriler ile banka hesap numarası, IBAN numarası, sözleşme bilgileri, finansal profil-performans bilgileri, malvarlığı verisi, tapu ve malvarlığı bilgileri, gelir bilgisi gibi veriler, bilanço bilgileri |

Fiziksel Mekan Güvenliği | Kamera kayıtları |

İşlem Güvenliği |

IP adres bilgileri, şifre ve parola bilgileri. |

Sağlık Bilgileri | Kan grubu, kişisel sağlık verileri |

Risk Yönetimi | Ticari, teknik, idari risklerin yönetilmesi için işlenen bilgiler, imza sirküleri, imza beyanı, vekaletname v.b. bilgiler |

6.2-Kişisel Veri İşlenme Amaçları:

Şirket tarafından özel nitelikli kişisel verileriniz dahil tüm kişisel verileriniz, yukarıda veri kategorileri başlığı altında yer alanlar dâhil ve bunlarla sınırlı olmaksızın, veri kategorileri ile bağlantılı ve ölçülü şekilde işbu Politikada yer alan amaçlara bağlı ve Kanunun 5. ve 6. Maddesinde yer alan hukuki sebepler belirlenerek işlenebilmektedir. Aydınlatma Metinlerinde, işlenen kişisel verilerinize, işleme amacı ve hukuki sebepleriyle eşleştirilerek her veri kategorisi bazında ayrı ayrı yer verilmektedir.

Şirket tarafından elde edilen ve bu bölümde yer verilen her türlü kişisel veriniz (Özel nitelikli kişisel veriler de dahil fakat bunlarla sınırlı olmamak kaydıyla) hukuka ve Kanun’un amacına uygun olarak Şirket’in;

1. Acil Durum Yönetimi Süreçlerinin Yürütülmesi

2. Bilgi Güvenliği Süreçlerinin Yürütülmesi

3. Faaliyetlerin Mevzuata Uygun Yürütülmesi

4. Finans Ve Muhasebe İşlerinin Yürütülmesi

5. Fiziksel Mekan Güvenliğinin Temini

6. Görevlendirme Süreçlerinin Yürütülmesi

7. Hukuk İşlerinin Takibi Ve Yürütülmesi

8. İç Denetim/ Soruşturma / İstihbarat Faaliyetlerinin Yürütülmesi

9. İletişim Faaliyetlerinin Yürütülmesi

10. İş Faaliyetlerinin Yürütülmesi / Denetimi

11. İş Sağlığı / Güvenliği Faaliyetlerinin Yürütülmesi

12. Lojistik Faaliyetlerinin Yürütülmesi

13. Mal / Hizmet Satın Alım Süreçlerinin Yürütülmesi

14. Mal / Hizmet Satış Sonrası Destek Hizmetlerinin Yürütülmesi

15. Mal / Hizmet Satış Süreçlerinin Yürütülmesi

16. Mal / Hizmet Üretim Ve Operasyon Süreçlerinin Yürütülmesi

17. Risk Yönetimi Süreçlerinin Yürütülmesi

18. Saklama Ve Arşiv Faaliyetlerinin Yürütülmesi

19. Sözleşme Süreçlerinin Yürütülmesi

20. Taşınır Mal Ve Kaynakların Güvenliğinin Temini

21. Tedarik Zinciri Yönetimi Süreçlerinin Yürütülmesi

22. Ürün / Hizmetlerin Pazarlama Süreçlerinin Yürütülmesi

23. Veri Sorumlusu Operasyonlarının Güvenliğinin Temini

24. Yatırım Süreçlerinin Yürütülmesi

25. Yetkili Kişi, Kurum Ve Kuruluşlara Bilgi Verilmesi

amaçları ile sınırlı kalmamak koşuluyla işlenebilecektir.

7. KİŞİSEL VERİLERİN TOPLANMA YÖNTEMİ VE HUKUKİ SEBEBİ

Kişisel veriler; Şirketimizin meşru menfaati gereği sizden bizzat talep ettiği bilgi ve dokümanlar, faaliyet konularımıza uygun düşecek şekilde; sözlü, yazılı, görsel ya da elektronik ortamda, internet sitesi, sözlü, yazılı, e-mail ile iletilen ve elde edilen bilgiler, iş ilişkisi kapsamında bizimle fiziksel ve dijital yolla paylaştığınız verileriniz, 3. Kişilerin ulaşımına açık kaydettiğiniz ve tarafınızca alenileştirilen aleni bilgi kayıtlarınız, ilettiğiniz finansal verileriniz, sözleşmelerde yer alan bilgileriniz, web sitelerimiz üzerinden yapılmış olan dijital başvurularınız, e-posta ve KEP yoluyla ilettiğiniz bilgiler, dilekçe ve başvurularınız, hukuki tebligatlar, Şirketimiz ile yapılan yazışmalarınız, , Şirkete hizmet vermekte olan İK kuruluşları ve hukuki yükümlülüklerimizi yerine getirmek için bize iletilen hukuki belge ve tebligatlar vasıtasıyla fiziksel ve dijital yollarla toplanmaktadır.

KVKK’nın 5. Maddesinin 1. Fıkrasında yer alan ‘Kişisel veriler ilgili kişinin açık rızası olmaksızın işlenemez’ düzenlemesi çerçevesinde, Şirketimiz KVKK’nın tanıdığı istisnai haller dışında, açık rızanın bulunması halinde kişisel veri işlemektedir.

KVKK 5. Madde 2.fıkra kapsamında, aşağıda belirtilen durumlarda Şirket kişisel veri sahiplerinin verilerini açık rıza almaksızın işleyebilmektedir;

‘’5/2-a:Kanunlarda açıkça öngörülmesi, 5/2-b: Fiili imkânsızlık nedeniyle rızasını açıklayamayacak durumda bulunan veya rızasına hukuki geçerlilik tanınmayan kişinin kendi sinin ya da bir başkasının hayatı veya beden bütünlüğünün korunması için zorunlu olması,5/2-c: “Bir sözleşmenin kurulması veya ifasıyla doğrudan doğruya ilgili olması kaydıyla, sözleşmenin taraflarına ait kişisel verilerin işlenmesinin gerekli olması”, Kişisel Verilerin Korunması Kanunu Mad. 5/2-ç: “Veri sorumlusunun hukuki yükümlülüğünü yerine getirebilmesi için zorunlu olması”, Kişisel Verilerin Korunması Kanunu Mad. 5/2-e: “ Bir hakkın tesisi, kullanılması veya korunması için veri işlemenin zorunlu olması” Kişisel Verilerin Korunması Kanunu Mad. 5/2-f) İlgili kişinin temel hak ve özgürlüklerine zarar vermemek kaydıyla, veri sorumlusunun meşru menfaatleri için veri işlenmesinin zorunlu olması ve hukuki sebep veya sebeplerine dayanarak işlenmektedir.

Şirket tarafından veri işleme faaliyeti başlanmadan önce, kişisel verilerinizle ilgili , KVKK 5. maddesi ve özel nitelikli verilerle ilgili KVKK 6. Maddesinde yer alan hukuki sebeplerden en az birinin varlığı tespit edilmediği takdirde mutlaka açık rıza temin edilmekte, açık rıza alınamaması durumunda veri işlenmemekte ve işleme hemen durdurulmaktadır.

8.KİŞİSEL VERİLERİN AKTARILMA AMAÇLARI

8.1-Kişisel Verilerin Aktarılması:

Şirketimiz hukuka uygun olan kişisel veri işleme amaçları doğrultusunda, gerekli güvenlik önlemlerini alarak, Kişisel Veri Sahibinin kişisel verilerini ve özel nitelikli kişisel verilerini KVKK madde 5’de yer alan şartlardan birinin varlığı halinde üçüncü kişilere ve kurumlara aktarabilmektedir.

Kanun 5. Madde kapsamında, aşağıda belirtilen durumlarda Şirket kişisel veri sahiplerinin verilerini açık rıza almaksızın aktarabilmektedir. Kişisel verileriniz, Kişisel Verilerin Korunması Kanunu Mad.5/2-c: “Bir sözleşmenin kurulması veya ifasıyla doğrudan doğruya ilgili olması kaydıyla, sözleşmenin taraflarına ait kişisel verilerin işlenmesinin gerekli olması”, Kişisel Verilerin Korunması Kanunu Mad. 5/2-ç: “Veri sorumlusunun hukuki yükümlülüğünü yerine getirebilmesi için zorunlu olması”, Kişisel Verilerin Korunması Kanunu Mad. 5/2-e: “ Bir hakkın tesisi, kullanılması veya korunması için veri işlemenin zorunlu olması” hukuki sebeplerine dayanarak aktarılabilmektedir.

Kişisel veriler, Şirket iş süreçlerinin gerçekleştirilmesi ve ayrıca yukarıda belirtilen amaçlarla; KVKK

8. ve 9. maddelerinde belirtilen kişisel veri aktarma şartları ile işbu Politika çerçevesinde sınırlı olarak ve kanunlarda öngörülmesi halinde ilgili mevzuat gereği resmi makamlara, yetkili kamu kurumlarına, gerçek veya özel hukuk tüzel kişilerine, sözleşmeye dayalı iş ilişkisinde olunan avukatlar, vergi ve finans danışmanları da dâhil olmak üzere danışmanlık alınan üçüncü kişilere, tedarikçilere, Şirket hissedar ve yetkililerine, iş ortakları ve topluluk şirketlerine aktarılabilmektedir.

Kişisel verileriniz KVKK Md. 28/1 çerçevesinde talep edilmesi halinde aydınlatma yükümlülüğü olmadan ve açık rızanız aranmadan ilgili makamlara aktarılabilir.

8.2-Özel Nitelikli Kişisel Verilerin Aktarılması:

Özel nitelikli kişisel veriler, Şirketimiz tarafından, işbu Politika’da belirtilen ilkelere uygun olarak ve gerekli güvenlik önlemleri alınarak KVKK madde 6’da yer alan şartların birinin varlığı halinde aktarılabilmektedir.

Özel nitelikteki verilerin aktarılabilmesi için aşağıda Kanunun 6. maddesinde de yer verilen istisnalar dışında veri sahibinin açık rızasının alınması zorunludur.

“Kişisel veri sahibinin sağlığına ve cinsel hayatına ilişkin özel nitelikli kişisel verileri ise ancak kamu sağlığının korunması, koruyucu hekimlik, tıbbi teşhis, tedavi ve bakım hizmetlerinin yürütülmesi, sağlık hizmetleri ile finansmanının planlanması ve yönetimi şeklinde olup; sır saklama yükümlülüğü altında bulunan kişiler veya yetkili kurum ve kuruluşlar tarafından açık rıza almadan” aktarılabilmektedir.

9.İŞLENEN KİŞİSEL VERİLERİN SAKLANMA SÜRELERİ

Şirket, Kişisel Verileri mevzuatta öngörülmesi durumunda, bu mevzuatta belirtilen süre boyunca saklamaktadır. Kişisel verilerin ne kadar süre boyunca saklanması gerektiğine ilişkin mevzuatta bir süre düzenlenmemişse, Kişisel Veriler Şirket’in o veriyi işlerken yürütülen faaliyet ile bağlı olarak Şirket’in uygulamaları ve ticari yaşamının teamülleri uyarınca işlenmesini gerektiren süre kadar işlenmekte daha sonra silinmekte, yok edilmekte veya anonim hale getirilmektedir.

Süreçlere bağlı olarak gerçekleştirilen faaliyetler kapsamındaki tüm kişisel verilerle ilgili kişisel veri bazında saklama süreleri Saklama ve İmha Politikasında yer alır.

Kişisel verilerin işlenme amacı sona ermiş; ilgili mevzuat ve Şirket’in belirlediği saklama sürelerinin de sonuna gelinmişse; kişisel veriler yalnızca olası hukuki uyuşmazlıklarda delil teşkil etmesi veya kişisel veriye bağlı ilgili hakkın ileri sürülebilmesi veya savunmanın tesis edilmesi amacıyla saklanabilmektedir. Buradaki sürelerin tesisinde bahsi geçen hakkın ileri sürülebilmesine yönelik zaman aşımı süreleri ile zaman aşımı sürelerinin geçmesine rağmen daha önce aynı konularda Şirket’e yöneltilen taleplerdeki örnekler esas alınarak saklama süreleri belirlenmektedir. Bu durumda saklanan kişisel verilere herhangi bir başka amaçla erişilmemekte ve ancak ilgili hukuki uyuşmazlıkta kullanılması gerektiği zaman ilgili kişisel verilere erişim sağlanmaktadır. Burada da bahsi geçen süre sona erdikten sonra kişisel veriler silinmekte, yok edilmekte veya anonim hale getirilmektedir.

Gelecekte kullanma ihtimali ile Şirket tarafından kişisel veriler saklanmamaktadır.

10. KİŞİSEL VERİLERİ SİLME, YOK ETME VE ANONİMLEŞTİRME YÜKÜMLÜLÜĞÜ

Kanunun 7. maddesinde, kişisel verilerin silinmesi, yok edilmesi ve anonim hale getirilmesi düzenlenmiştir. Buna göre, kişisel verilerin hukuka uygun olarak işlenmiş olmasına rağmen, işlenmesini gerektiren sebeplerin ortadan kalkması hâlinde bu veriler, resen veya ilgili kişinin talebi üzerine veri sorumlusu tarafından silinir, yok edilir veya anonim hâle getirilir

Özellikle aşağıda sayılan hallerde kişisel verilerin işlenme şartlarının ortadan kalktığı kabul edilmektedir:

- Kişisel verileri işlemeye esas teşkil eden ilgili mevzuat hükümlerinin değiştirilmesi veya kaldırılması,

- Taraflar arasındaki sözleşmenin hiç kurulmamış olması, sözleşmenin geçerli olmaması, sözleşmenin kendiliğinden sona ermesi, sözleşmenin feshi veya sözleşmeden dönülmesi,

- Kişisel verilerin işlenmesini gerektiren amacın ortadan kalkması,

- Kişisel verileri işlemenin hukuka veya dürüstlük kuralına aykırı olması,

- Kişisel verileri işlemenin sadece açık rıza şartına istinaden gerçekleştiği hallerde, ilgili kişinin rızasını geri alması,

- İlgili kişinin, Kanunun 11. maddesinin (e) ve (f) bentlerindeki hakları çerçevesinde kişisel verileri işleme faaliyetine ilişkin yaptığı başvurunun veri sorumlusu tarafından kabul edilmesi,

- Veri sorumlusunun, ilgili kişi tarafından kişisel verilerinin silinmesi veya yok edilmesi talebi ile kendisine yapılan başvuruyu reddetmesi, verdiği cevabın yetersiz bulunması veya Kanunda öngörülen süre içinde cevap vermemesi hallerinde; Kurula şikayette bulunulması ve bu talebin Kurul tarafından uygun bulunması,

- Kişisel verilerin saklanmasını gerektiren azami sürenin geçmiş olmasına rağmen, kişisel verileri daha uzun süre saklamayı haklı kılacak herhangi bir şartın mevcut olmaması,

- Kanunun 5. ve 6. maddelerindeki kişisel verilerin işlenmesini gerektiren şartların ortadan kalkması; Belirtilen hallerde kişisel veriler, veri sorumlusu tarafından resen veya ilgili kişinin talebi üzerine silinir, yok edilir veya anonim hale getirilir.

Kişisel verilerin silinmesi işlemi, “söz konusu kişisel verilerin ilgili kullanıcılar tarafından hiçbir şekilde erişilemez ve tekrar kullanılamaz hale getirilmesi” olarak tanımlanmıştır. Bu kapsamda, bir verinin işlenmesini gerektiren sebeplerin ortadan kalkması halinde, söz konusu verinin yedeklemeler dahil tüm ortamlardan geri dönülmez şekilde silinmesi sağlanmaktadır

Kişisel verilerin silinmesi ve yok edilmesi teknikleri ve kişisel verilerin anonim hale getirilmesi tekniklerinden hangisinin uygulanacağına dair karar Veri Koruma Görevlisi tarafından verilir.

Silme işlemine konu teşkil edecek kişisel veriler belirlenir. Silme işlemleri önceden belirlenmiş kişi vasıtasıyla yerine getirilir. Bu kişinin yetkileri özel olarak düzenlenir. Silme işlemi yapan kişinin silinen datayı geri getirme, tekrar kullanma erişim yetkileri kaldırılır.

Silinmesi gereken verilerin silme, yok etme veya anonimleştirilmesinin, kanun, yönetmelik ve Şirket politika ve prosedürlerine uygun olarak yapıldığının ve işlemlere ilişkin oluşturulan bilgi kaydı doğruluğunun kontrolü Şirket Veri Koruma Görevlisi tarafından yapılır.

11.KİŞİSEL VERİ SAHİBİNİN AYDINLATILMASI VE BİLGİLENDİRİLMESİ

Şirket, Kanun’un 10. maddesine uygun olarak, Kişisel Verilerin elde edilmesi sırasında Kişisel Veri Sahiplerini aydınlatmaktadır. Bu kapsamda, kişisel verilerin kim tarafından, hangi amaçlarla işlenebileceği, işlenen Kişisel Verilerin kimlere ve hangi amaçlarla aktarılabileceği, kişisel veri toplamanın yöntemi ve hukuki sebebi ile kişisel veri sahibinin sahip olduğu hakları konusunda aydınlatma yapmaktadır.

KVKK madde 10 kapsamında, “Aydınlatma Metni” ile verisi işlenecek gerçek kişilere iletilerek bilgilendirme yapılmaktadır. Ortak/Hissedar, Potansiyel Ürün ve/veya Hizmet Alıcıları Çalışanları, Ürün ve/veya Hizmet Alıcıları Çalışanları, Tedarikçi Çalışanı/Yetkilisi, Ziyaretçi, sözleşmeye dayalı çalışma yapılan Müşavirler, Hukuk Danışmanlarının, sözleşme ve iş ilişkisi kapsamında kişisel verileri işlenen diğer üçüncü şahısların bilgilendirilmesine yönelik Genel Aydınlatma Metni’ne Şirketimiz web sitesinde yer verilmekte ve şirket içerisinde fiziki şekilde tutularak ilgililerin incelemesine sunulmaktadır.

Anayasa’nın 20. maddesinde herkesin, kendisiyle ilgili kişisel veriler hakkında bilgilendirilme hakkına sahip olduğu ortaya konulmuştur. Bu doğrultuda KVK Kanunu’nun 11. maddesinde kişisel veri sahibinin hakları arasında “bilgi talep etme” hakkına yer verilmiştir.

Şirket KVK Kanunu’nun 11. maddelerine uygun olarak Kişisel Veri Sahibinin bilgi talep etmesi durumunda, ilgili kişiye gerekli bilgilendirmeleri süresi içinde yapmaktadır. Başvuru cevaplanmasının zamanında ve hukuka uygun yapılmasını teminen ‘Başvuru Cevaplama Prosedürü’ düzenleyerek Şirket içinde sorumlu kişiler belirlenmiş ve görevlendirilmiştir.

12.VERİ SAHİBİNİN HAKLARI VE BU HAKLARINI KULLANMASI

12.1-Kişisel Veri Sahibinin KVKK Uyarınca Hakları:

Şirketimizce KVKK madde 11’e uygun olarak Kişisel Veri Sahibinin bilgi talep etmesi durumunda, ilgili kişiye gerekli bilgilendirmeleri süresi içinde yapılmaktadır. Başvurulara cevap verilmesi zamanında ve hukuka uygun olarak gerçekleştirilmektedir.

Şirket, Kanun’un 11.maddesi uyarınca Kişisel Verileri alınan kişilere;

-Kişisel Veri işlenip işlenmediğini öğrenme,

-Kişisel Verileri işlenmişse buna ilişkin bilgi talep etme,

-Kişisel Verilerin işlenme amacını ve bunların amacına uygun kullanılıp kullanılmadığını öğrenme,

-Yurt içinde veya yurt dışında Kişisel Verilerin aktarıldığı üçüncü kişileri bilme,

-Kişisel Verilerin eksik veya yanlış işlenmiş olması halinde bunların düzeltilmesini isteme,

-Kanun’un 7. maddesinde öngörülen şartlar çerçevesinde Kişisel Verilerin silinmesini veya yok edilmesini isteme,

-Kanun’un 11. Maddesinin (d) ve (e) bentleri uyarınca yapılan işlemlerin, kişisel verilerin aktarıldığı üçüncü kişilere bildirilmesini isteme,

-İşlenen verilerin münhasıran otomatik sistemler vasıtasıyla analiz edilmesi suretiyle kişinin kendisi aleyhine bir sonucun ortaya çıkmasına itiraz etme,

-Kişisel Verilerin kanuna aykırı olarak işlenmesi sebebiyle zarara uğraması halinde zararın giderilmesini talep etme haklarının olduğunu açıklar.

12.2-Kişisel Veri Sahibinin Haklarını Kullanması:

Veri sahibi, KVKK’nın 13. maddesinin 1. fıkrası gereğince yukarıda 11. madde kapsamında sayılan hakları kullanabilir.

KVKK’nın 11. maddesinde belirtilen hakların kullanılması için;

Başvurunuzu “Hacımimi Mah. Kemeraltı Cad. No.15 Kat 3 34424 Karaköy/ İstanbul” adresine bizzat teslim edebilir, noter kanalı ile gönderebilir veya (KEP)Kayıtlı Elektronik Posta adco@hs01.kep.tr adresine güvenli elektronik imza, mobil imza, ya da ilgili kişi tarafından veri sorumlusuna daha önce bildirilen ve veri sorumlusunun sisteminde kayıtlı bulunan elektronik posta adresiniz kanalıyla iletebilirsiniz. Veri Sahibinin talebi, niteliğine göre en kısa sürede ve en geç otuz gün içinde ücretsiz olarak sonuçlandırılır. İşlemin Şirket için ayrıca bir maliyet oluşturması halinde, Veri Sorumlusuna Başvuru Usul ve Esasları Hakkında Tebliğ’de belirtilen ücret talep edilebilecektir. Talebin reddedilmesi halinde, red nedenleri Veri Sahibine yazılı olarak veya elektronik ortamda gerekçeleriyle bildirilir. Kişisel veri sahipleri adına üçüncü kişiler tarafından talepte bulunulması mümkün değildir.

Kişisel veri sahibinin kendisi dışında bir kişinin talepte bulunması için konuya ilişkin olarak kişisel veri sahibi tarafından başvuruda bulunacak kişi adına düzenlenmiş özel vekâletname bulunmalıdır.

Kişisel veri sahibi, KVKK’nın 14. Maddesi gereğince başvurusunun reddedilmesi, verilen cevabın yetersiz bulunması veya süresinde başvuruya cevap verilmemesi hallerinde, Şirketin cevabını öğrendiği tarihten itibaren otuz ve her halükarda başvuru tarihinden itibaren altmış gün içinde KVK Kuruluna şikayette bulunabilir.

12.3-Şirketin Kişisel Veri Sahibinin Başvurusunu Reddetme Hakkı:

Şirket aşağıda yer alan hallerde başvuruda bulunan kişinin başvurusunu, gerekçesini açıklayarak reddedebilir:

- Kişisel veri sahibi tarafından kendisi tarafından alenileştirilmiş kişisel verilerin işlenmesi.

- Kişisel veri sahibinin talebinin diğer kişilerin hak ve özgürlüklerini engelleme ihtimali olması,

- Talep edilen bilginin kamuya açık bir bilgi olması.

- Kişisel verilerin anonim hâle getirilmek suretiyle araştırma, planlama ve istatistik gibi resmi amaçlarla işlenmesi.

- Kişisel verilerin millî savunma, millî güvenlik ve kamu güvenliği, ekonomik güvenlik alanlarında kamu düzeni sağlamaya yönelik kanunla yetki verilen kamu kuruluşları ve kurumları tarafından yürütülen güvenlik ve istihbarat faaliyet kapsamında işlenmesi.

- Kişisel verilerin soruşturma, kovuşturma, yargılama veya infaz işlemlerine ilişkin olarak yargı tarafından işlenmesi.

- Kişisel veri işlemenin görevli ve yetkili kamu kurum ve kuruluşları tarafından yürütülen soruşturma veya inceleme için gerekli olması.

Şirket başvuruda bulunan kişinin kişisel veri sahibi olup olmadığını tespit etmek adına ilgili kişiden ek bilgi ve belge talep edebilir ve kişisel veri sahibine başvurusunda yer alan hususlarla ilgili soru yöneltebilir.

13. KİŞİSEL VERİLERİN GÜVENLİĞİNİN SAĞLANMASI

Şirket, bilginin bütünlüğünü koruyacak ve sürekli erişilebilirliğini garanti altına alacak alt yapıyı ve kontrolleri hayata geçirmiştir. Kişisel verilerin tedbirsizlikle veya yetkisiz olarak açıklanmasını, erişimini, aktarılmasını veya başka şekillerdeki hukuka aykırı erişimi önlemek için ve oluşabilecek diğer teknik tehditler karşısında korunacak verinin niteliğine göre, aşağıda yer verilen teknik ve idari tedbirleri uygulamaya koymuştur.

13.1-Teknik Tedbirler:

Güvenlik sistemi kişisel verilerin kişilere ait bilgi sistemlerinde bulunduğu esnada tüm tehditlere karşı korunmasıdır.

Bilgi güvenliği tehditleri arasında, Şirket bünyesinde çalışan kişilerin oluşturabileceği bilinçli veya bilinçsiz tehditler olarak tanımlayabileceğimiz iç tehditler çok önemli bir yer tutmaktadır.

Şirket bünyesinde çalışan kişilerin oluşturabileceği bilinçli veya bilinçsiz tehditler dikkate alınarak bilgiye erişimi kontrol etmek ve yetkisiz erişimleri önlemek için ilgili tüm alanlarda gerekli güvenlik kontrollerini hayata geçirilmiştir.

Çalışanların günlük faaliyetlerinin yetki profillerine uyum sağlayıp sağlamadığı Şirket bilgi sistem birimi tarafından düzenli olarak kontrol edilmektedir.

Yetki düzeyi onayları Veri Koruma Görevlisi tarafından verilmektedir.

Kişisel veri kaynaklarına erişim için personel veya üçüncü şahıslar tarafından kullanılan şifreler, ilgili sistemler için tanımlanmış olan şifre belirleme kurallarına uyumlu olarak düzenlenmektedir.

Şirkette dış ağlardan gelebilecek tehditlere karşı katmanlı ağ güvenlik tedbirleri tesis edilmiştir. Kurum Bilgisayar sistemlerinde anti virüs yazılımları, güvenlik duvarları, merkezi yönetim yazılımları kullanılmaktadır.

Virüslerin en çok yayıldığı servisler olan e-mail, http ve ftp trafikleri firewall mantığı esas alınarak anti virüs ağ geçidine yönlendirilir. Buradaki tarama işleminden sonra gerekli yerlere yönlendirilme yapılır. Bu sistemle dışarıdan gelecek olan virüsler engellenmiş olur. Mail sunucuları üzerine kurulan anti virüs sistemiyle yerel ağ içerisinde e-mail aracılığıyla dolaşan virüslerde etkisiz hale getirilmiş olur.

Sunucu bilgisayarları üzerine kurulan virüs koruma yazılımları ve Şirket çalışanlarının sistemlerini kontrol edecek yazılımlarla Şirket içerisinde kurumsal anti virüs çözümü sağlanmış olmaktadır. Bu denetleme çalışmaları; bilinen açıklara karşı güvenlik taraması, uygulama tipine göre uygulamaya yönelik güvenlik taramaları ve sistem yapılandırma kontrollerini kapsamaktadır. Kullanılan log programları sistem yöneticilerinin sistemi güçlü bir şekilde izlemesine yardımcı olmaktadır. Yedekleme için yedekleme prosedürü düzenlenerek kritik sistemlerin yedekleri periyodik olarak alınmakta, yedekler belirli aralıklarla dış ortama taşınmakta ve belirlenen zamanlarda geri dönüş testleri yapılmaktadır.

13.2- İdari Tedbirler:

Şirketimizin Veri Güvenliğine ilişkin hazırladığı politikaların temel amacı, yürütülen kişisel veri işleme faaliyeti ve kişisel verilerin korunmasına yönelik süreçler hakkında açıklamalarda bulunmak, kişisel verileri Şirket tarafından işlenen veri sahibi gerçek kişileri bilgilendirmek, uygulamada şeffaflığı ve veri güvenliğini ve Kanuna uyumu sağlamaktır.

Şirket bünyesinde işlenen kişisel verilere karşı iç ve dış ağlardan gelebilecek tehlikelerin işlendiği ‘Risk ve Tehditler Tablosu’ Veri Güvenlik Komitesi tarafından periyodik incelenmekte ve tedbirler güncellenmektedir

Uygulamalar üzerinde teknik kontrol sistemleri kurulmuştur. Veri sorumlusu olarak kurum içi sistematik periyodik denetimleri Veri Koruma Görevlisi kanalıyla yapmaktadır. Denetimler gerek görüldüğünde uzman şirketlere veya bağımsız denetim şirketlerine yaptırılacaktır.

Bilgiye erişimi kontrol etmek ve yetkisiz erişimleri önlemek, veri güvenliğini sağlamak, hukuka uygun saklama ve imha işlemleri uygulamaları için ilgili alanlarda, “Kimlik Yönetimi ve Yetkilendirme Prosedürü” ve “Kişisel Veri Saklama ve İmha Politikası” hazırlanmış ve uygulamaya alınmıştır. Veri ihlalinin tespiti halinde Kişisel Verilerin Korunması Kurulu ve veri sahiplerinin bilgilendirilmesi ihlalle ilgili önleyici tedbirlerin derhal alınmasının sağlanmasını teminen Veri İhlali Müdahale Planı ve Veri İhlali Bildirim Prosedürü yürürlüğe konularak görevlendirmeler yapılmıştır.

Gizlilik taahhütnameleri; “Veri sorumluları ile veri işleyen gerçek veya tüzel kişiler, öğrendikleri kişisel verileri KVKK hükümlerine aykırı olarak başkasına açıklayamazlar. Bu yükümlülük görevden ayrılmalarından veya hizmet sözleşmelerinin sona ermesinden sonra da devam eder. Şirketimizce çalışan istihdam edilmesi halinde bu hüküm yürürlüğe konacaktır.

Kanunun 12. Maddesi ikinci fıkrası gereği Veri İşleyenler, kişisel verilerin güvenliğinin sağlanması konusunda veri sorumlusu ile müştereken sorumludur.” hükmü kapsamında;

Kanuna ve gizlilik esaslarına uyumu içeren ve veri sorumlusu yükümlülüklerine veri işleyenleri de tabi tutan ve kanunu ihlal durumunda veri işleyeni de müşterek sorumlu tutan hükmü içeren sözleşmesi veri işleyenlere imzalatılmaktadır. Şirket tarafından kişisel verilerin hukuka uygun olarak aktarıldığı kişi ve şirketler ile yapılan ve yapılacak sözleşmelere; kişisel verilerin korunması amacıyla gerekli güvenlik ve gizlilik tedbirlerini alacağına ve kendi kuruluşlarında bu tedbirlere uyulmasını sağlayacağına dair müşterek sorumluluk hükümleri eklenmektedir.

Veri gizliliğinin sağlanması ve güvenlik tedbirlerine uyulması konusunda tüm çalışanlardan (istihdam edilmesi halinde) ve veri işleyen diğer şahıs veya kurumlardan taahhütname alınması zorunlu kılınmıştır.

Çalışanlar (istihdam edilmesi halinde ), danışmanlar, bilgi sistem destek şirketleri ve diğer üçüncü kişi veya şirketler yapılan sözleşmelere de bu kapsamda gizlilik taahhütnameleri eklenmektedir.

Şirket, kişisel verilerin hukuka aykırı olarak işlenmesini, verilere hukuka aykırı olarak erişilmesini önlemeye ve verilerin muhafazasını sağlamaya yönelik farkındalığın artırılması için iş birimlerine gerekli eğitimlerin düzenlenmesini sağlamaktadır.

Şirket çalışanlarının (istihdam edilmesi halinde) kişisel verileri özel veya ticari amaçlarla kullanması, bu verileri yetkisiz kişilerle paylaşması veya başka bir yöntemle bu verileri erişilebilir hale getirmeleri yasaktır.

Şirket çalışanlarının (istihdam edilmesi halinde) kişisel bilgilere ancak söz konusu görevlerinin türü ve kapsamı çerçevesinde yetkiye dayalı şekilde erişebilir. Bunun için rol ve sorumlulukların detaylandırılması, ayrıştırılması ve hayata geçirilmesi yetki matrisi ile sağlanmıştır.

Şirket çalışan istihdam edilmesi halinde bu çalışanların kişisel verilerin korunması konusunda farkındalığının oluşması için gerekli sistemler kurmakta, eğitimler vermekte konuya ilişkin ihtiyaç duyulması halinde danışmanlar ile çalışmaktadır.

14. POLİTİKA’NIN VE İLGİLİ MEVZUATIN UYGULANMASI

Kişisel verilerin işlenmesi ve korunması konusunda yürürlükte bulunan ilgili kanuni düzenlemeler öncelikle uygulama alanı bulacaktır. Yürürlükte bulunan mevzuat ve Şirket Politika arasında uyumsuzluk bulunması durumunda, Şirketimiz yürürlükteki mevzuatın uygulama alanı bulacağını kabul etmektedir.

15. POLİTİKA’NIN YÜRÜRLÜĞÜ

Şirket tarafından düzenlenen işbu Politika 23.11.2023 tarihlidir. Politika’nın tamamının veya belirli maddelerinin yenilenmesi durumunda Politika’nın yürürlük tarihi güncellenecektir. Politika Şirketin internet sitesinde yayınlanır, bu Politikanın gözden geçirme ve güncellenmesi Şirket tarafından yetkilendirilen Veri Koruma Görevlisi tarafından yerine getirilir Politika her yıl en az bir kez gözden geçirilir.

AVRASYA TEKNOLOJİ MÜHENDİSLİK VE İNŞAAT ANONİM ŞİRKETİ

GENEL AYDINLATMA METNİ

AVRASYA TEKNOLOJİ MÜHENDİSLİK VE İNŞAAT ANONİM ŞİRKETİ (“AVRASYA” veya “ŞİRKET”) olarak; veri sorumlusu sıfatıyla, kişisel verilerinizin güvenliği hususuna verdiğimiz önem doğrultusunda bünyemizde barındırdığımız her türlü kişisel veri 6698 sayılı Kişisel Verilerin Korunması Kanunu (“KVKK”)’na uygun olarak işlenmekte, saklanmakta ve aktarılmaktadır. Bu sorumluluğumuz kapsamında KVKK’da tanımlı şekli ile “Veri Sorumlusu” sıfatıyla, kişisel ve özel nitelikli kişisel verilerinizi (“kişisel veri”) aşağıda açıklandığı surette ve mevzuatta yer alan sınırlar çerçevesinde işlemekteyiz. İşbu Aydınlatma Metninde kullanılan kişisel veri, özel nitelikli kişisel veri, veri işleme, ilgili kişi ve veri sorumlusu kavramları KVKK’da yapılan tanımlara istinaden kullanılmıştır.

İşbu aydınlatma metni Şirketimiz tarafından toplanan, saklanan ve işlenen kişisel verilerinize ilişkin olarak KVKK kapsamında Aydınlatma Yükümlülüğünün Yerine Getirilmesi doğrultusunda Ortak/Hissedar, Potansiyel Ürün ve/veya Hizmet Alıcıları Çalışanları, Ürün ve/veya Hizmet Alıcıları Çalışanları, Tedarikçi Çalışanı/Yetkilisi, Ziyaretçi, sözleşmeye dayalı çalışma yapılan Müşavirler, Hukuk Danışmanlarının, sözleşme ve iş ilişkisi kapsamında kişisel verileri işlenen diğer üçüncü şahısların bilgilendirilmesi amacıyla hazırlanmıştır.

1. VERİ SORUMLUSU

Kişisel verileriniz; Veri Sorumlusu olarak AVRASYA tarafından KVKK uyarınca aşağıda açıklandığı şekilde yasal mevzuat kapsamında öngörülen sınırlar çerçevesinde işlenebilecektir.

VERİ SORUMLUSU BİLGİLERİ

Veri Sorumlusu Şirket Unvanı : AVRASYA TEKNOLOJİ MÜHENDİSLİK VE İNŞAAT A.Ş.

Telefon Numarası: +90 (212) 252 08 40

E-Posta: aylin.bulut@adco.com.tr

Adres: Hacımimi Mah. Kemeraltı Cad. No.15 Kat 3 Karaköy 34425 İstanbul

KEP Adresi: avrasyateknoloji@hs01.kep.tr

2. KİŞİSEL VERİ KATEGORİLERİ İLE İŞLENME VE AKTARILMA AMAÇLARI

KVKK’nın 4. Maddesi’nde belirtilen ilkelere bağlı olarak kategorize edilen kişisel verileriniz, aşağıda yer alan amaçlar doğrultusunda işlenmektedir:

Kimlik Verisi: Ad, soyadı, doğum tarihi, doğduğu ülke, doğduğu şehir, cinsiyet, medeni durumu, milliyeti, TC kimlik kartı üzerindeki bilgileri (TCKN, seri no, cüzdan numarası ile sıra no, cilt no, kayıt no, nüfusa kayıtlı olunan il/ilçe/köy/mahalle, verildiği yer, veriliş sebebi, veriliş tarihi, imza bilgisi vb. bilgiler İletişim Verisi: Adres bilgisi, adres no, telefon numarası, e-posta adresi, cep telefonu numarası, kurumsal e-posta adresi, kep adresi, şirket içi iletişim bilgileri, dahili telefon numarası vb. bilgiler:

Acil Durum Yönetimi Süreçlerinin Yürütülmesi, Bilgi Güvenliği Süreçlerinin Yürütülmesi, Faaliyetlerin Mevzuata Uygun Yürütülmesi, Finans Ve Muhasebe İşlerinin Yürütülmesi, Fiziksel Mekan Güvenliğinin Temini, Görevlendirme Süreçlerinin Yürütülmesi, Hukuk İşlerinin Takibi Ve Yürütülmesi, İç Denetim/ Soruşturma / İstihbarat Faaliyetlerinin Yürütülmesi, İletişim Faaliyetlerinin Yürütülmesi, İş Faaliyetlerinin Yürütülmesi / Denetimi, İş Sağlığı / Güvenliği Faaliyetlerinin Yürütülmesi, Lojistik Faaliyetlerinin Yürütülmesi, Mal / Hizmet Satın Alım Süreçlerinin Yürütülmesi, Mal / Hizmet Satış Sonrası Destek Hizmetlerinin Yürütülmesi, Mal / Hizmet Satış Süreçlerinin Yürütülmesi, Risk Yönetimi Süreçlerinin Yürütülmesi, Saklama Ve Arşiv Faaliyetlerinin Yürütülmesi, Sözleşme Süreçlerinin Yürütülmesi, Taşınır Mal Ve Kaynakların Güvenliğinin Temini, Tedarik Zinciri Yönetimi Süreçlerinin Yürütülmesi, Ürün / Hizmetlerin Pazarlama Süreçlerinin Yürütülmesi, Veri Sorumlusu Operasyonlarının Güvenliğinin Temini, Yatırım Süreçlerinin Yürütülmesi, Yetkili Kişi, Kurum Ve Kuruluşlara Bilgi Verilmesi amaçlarıya;

Finans: Her türlü finansal sonucu gösteren bilgi, belge ve kayıtlara ilişkin işlenen kişisel veriler ile banka hesap numarası, IBAN numarası, finansal profil-performans bilgileri, malvarlığı verisi, gelir bilgisi gibi veriler, bilanço bilgileri: Muhasebe kaydı ve cari kart açılması ve Finans ve Muhasebe İşlerinin Yürütülmesinin sağlanması ve bu konularla ilgili sizlerle iletişim kurmak, İç Denetim/ Soruşturma / İstihbarat Faaliyetlerinin Yürütülmesi, Mal / Hizmet Satın Alım Süreçlerinin Yürütülmesi, Mal / Hizmet Satış Süreçlerinin Yürütülmesi, Sözleşme Süreçlerinin Yürütülmesi, i, Yetkili Kişi, Kurum Ve Kuruluşlara Bilgi Verilmesi, Faaliyetlerin Mevzuata Uygun Yürütülmesi, Hukuk İşlerinin Takibi Ve Yürütülmesi, Yatırım Süreçlerinin Yürütülmesi amaçlarıyla,

Fiziksel Mekan Güvenliği: Kamera kayıtları: Fiziksel mekân güvenliğinin sağlanması ve Ziyaretçi kayıtlarının oluşturulması ve takibi, amaçlarıyla,

Lokasyon: Araç takip sistemleri verileri. Ürün takibi amacıyla İç Denetim/ Soruşturma / İstihbarat Faaliyetlerinin Yürütülmesi (kaza-ceza halinde), İş Faaliyetlerinin Yürütülmesi / Denetimi, Veri Sorumlusu Operasyonlarının Güvenliğinin Temini (satış yapılan ürünün takibi için lojistik görevlisinin konumu)

Risk Yönetimi: Ticari, teknik, idari risklerin yönetilmesi için işlenen bilgiler, imza sirküleri, imza beyanı, vekaletname v.b. bilgiler: Faaliyetlerin Mevzuata Uygun Yürütülmesi, Mal / Hizmet Satış Süreçlerinin Yürütülmesi amaçlarıyla

Hukuki İşlem: Vekaletname, hukuki alacak ve haklarının tespiti, takibi ve borçlarının ifası ile kanuni yükümlülükler kapsamında işlenen veriler: Yetkili ve görevli kamu kurum ve kuruluşlarına karşı diğer hukuki yükümlüklerimizi yerine getirmek ve aramızda doğabilecek uyuşmazlıklarda delil olarak kullanılmak, faaliyetlerin mevzuata uygun yürütülmesi amaçlarıyla,

İşlem Güvenliği: şifre, ip adresi vb. Bilgi güvenliği süreçlerinin yürütülmesi, Faaliyetlerin Mevzuata Uygun Yürütülmesi, Hukuk İşlerinin Takibi Ve Yürütülmesi, İç Denetim/ Soruşturma / İstihbarat Faaliyetlerinin Yürütülmesi, Risk Yönetimi Süreçlerinin Yürütülmesi, Veri Sorumlusu Operasyonlarının Güvenliğinin Temini, Yetkili kişi, kurum ve kuruluşlara bilgi verilmesi

Müşteri İşlem: Kimlik ve fatura bilgileri (TC kimlik numarası, vergi numarası, şahıs şirketi bilgileri), iban bilgileri, mal/hizmet teklif ve talep bilgisi vb. bilgiler: Faaliyetlerin Mevzuata Uygun Yürütülmesi, Finans Ve Muhasebe İşlerinin Yürütülmesi, Hukuk İşlerinin Takibi Ve Yürütülmesi, İç Denetim/ Soruşturma / İstihbarat Faaliyetlerinin Yürütülmesi, Lojistik Faaliyetlerinin Yürütülmesi, Mal / Hizmet Satın Alım Süreçlerinin Yürütülmesi, Mal / Hizmet Satış Sonrası Destek Hizmetlerinin Yürütülmesi, Mal / Hizmet Satış Süreçlerinin Yürütülmesi, Mal / Hizmet Üretim Ve Operasyon Süreçlerinin Yürütülmesi, Risk Yönetimi Süreçlerinin Yürütülmesi, Yetkili Kişi, Kurum Ve Kuruluşlara Bilgi Verilmesİ

3. İŞLENEN KİŞİSEL VERİLERİN KİMLERE VE HANGİ AMAÇLA AKTARILABİLECEĞİ

Şirket, Kanunun 5. Maddesine, 6. maddesinde yer alan Özel Nitelikli Kişisel verilerin işlenmesine ilişkin ve

8. ve 9. maddelerde yer alan kişisel verilerin aktarılması konusunda öngörülen düzenlemelere ve Kişisel Verileri Koruma Kurumu tarafından yayımlanan esaslara uygun davranmaktadır. Özel nitelikli veriler veri sahibinin açık rızasının alınmadan aktarılmamaktadır.

Kişisel verileriniz, Kanun ve sair mevzuat kapsamında mevzuattan kaynaklanan yükümlülükleri yerine getirmek amacıyla yetkili ve görevli kamu kurum ve kuruluşlarına, yetkili kişi, kurum ve kuruluşlara bilgi verilmesi amacıyla denetleyici ve düzenleyici kurumlara, aramızda doğabilecek hukuki uyuşmazlıklarda delil olarak kullanılmak amacıyla her türlü yargı makamına, yetki vermiş olduğunuz temsilcileriniz ve avukatlara, İş faaliyetlerinin yürütülmesi / denetimi ve faaliyetlerin mevzuata uygun yürütülmesi amaçlarıyla hissedarlara, vergi ve finans danışmanları da dâhil olmak üzere danışmanlık aldığımız üçüncü kişilere, grup şirketlerimize, iş ortaklarımıza, sözleşmeye dayalı iş ilişkisinde olduğumuz mesleki uzman ve uzman yardımcılarına, danışman ve müşavirlerine, hizmet/mal tedarikçilerine, kargo şirketlerine aktarabilmektedir.

4. KİŞİSEL VERİLERİNİZİN TOPLANMA YÖNTEMİ VE HUKUKİ SEBEBİ

KVKK’nın 10 uncu maddesinin birinci fıkrasının (ç) bendinde yer alan “hukuki sebep” ile kastedilen, aydınlatma yükümlülüğü kapsamında kişisel verilerin Kanunun 5 ve 6. maddelerinde belirtilen işleme şartlarından hangisine dayanılarak işlendiğidir.

Kişisel veriler, meşru menfaat gereği sizden bizzat talep ettiğimiz bilgiler, iş ilişkisi kapsamında bizimle fiziksel ve dijital yolla paylaştığınız kişisel verileriniz; sözleşme bilgileriniz, ilettiğiniz finansal veri ve fatura bilgileriniz, web sitelerimiz üzerinden yapılmış olan dijital başvurularınız, e-posta ve KEP yoluyla ilettiğiniz bilgiler, dilekçe ve başvurularınız, hukuki tebligatlar, Şirketimiz ile yapılan yazışmalarınız, kargo gönderileri, KVKK Mad.11 kapsamında Şirketimize yapılan başvurular da dahil her türlü iletişim kanalları ile toplanan veriler, hizmet tedarik işlemlerinin yürütülmesi sırasında, operasyon destek işlemleri sırasında, (irsaliye, fatura düzenleme, iade faturası kabulü vb.), muhasebe işlemleri sırasında, gelen taleplerin değerlendirilmesi sonucu, satın alma işlemleri sırasında elde edilen veriler ile sözlü olarak aktardığınız bilgilendirmeler, sosyal medya hesapları kanalları ile paylaştığınız veriler; elektronik ve fiziksel ortamlarda toplanmakta olup yasal süreler ve işin gerektirdiği şartlar kapsamında saklanmaktadır.

Kişisel verileriniz, Kişisel Verilerin Korunması Kanunu Mad. 5/2-c : “Bir sözleşmenin kurulması veya ifasıyla doğrudan doğruya ilgili olması kaydıyla, sözleşmenin taraflarına ait kişisel verilerin işlenmesinin gerekli olması”, Kişisel Verilerin Korunması Kanunu Mad. 5/2-ç: “Veri sorumlusunun hukuki yükümlülüğünü yerine getirebilmesi için zorunlu olması”, Kişisel Verilerin Korunması Kanunu Mad. 5/2-e: “Bir hakkın tesisi, kullanılması veya korunması için veri işlemenin zorunlu olması” ve 5/2-f maddesinde belirtilen “ilgili kişinin temel hak ve özgürlüklerine zarar vermemek kaydıyla veri sorumlusunun meşru menfaati için zorunlu olması” hukuki sebeplerinden en az birine ve gerektiğinde Açık Rıza hükmüne dayanarak toplanmakta ve işlenmektedir.

Şirketimiz de geçerli bir amaç ve geçerli bir hukuki sebebe veya açık rıza uygulamasına dayanmadan veri toplanmamaktadır.

5. KİŞİSEL VERİ SAHİBİN HAKLARI VE BAŞVURU ŞEKLİ

Şirketimiz, KVK Kanunu’nun 10. maddesine uygun olarak kişisel veri sahibinin haklarını kendisine bildirmekte, bu hakların nasıl kullanılacağı konusunda kişisel veri sahibine yol göstermektedir.

Kişisel veri sahipleri, KVKK madde 11 kapsamında, Şirketimize başvurarak;

a)Kişisel verilerinin işlenip işlenmediğini öğrenme, b)Kişisel verileri işlenmişse bunun hakkında bilgi talep etme, c)Kişisel verilerinin işlenme amacını ve amacına uygun kullanılıp kullanılmadığını öğrenme, ç)Kişisel verilerini yurt içinde veya yurt dışında aktarıldığı 3. kişileri bilme, d)Kişisel verileri eksik veya yanlış işlenmişse, bunların düzeltilmesini isteme, e)KVKK’nın 7. maddesinde öngörülen şartlar çerçevesinde şirketimizin hukuki yükümlülükleri saklı kalmak kaydı ile silinmesini veya yok edilmesini isteme, f)Kişisel verilerinin aktarıldığı 3. kişilere yukarıda sayılan (d) ve (e) bentleri uyarınca yapılan işlemlerin bildirilmesini isteme, g)Kişisel verilerinin münhasıran otomatik sistemler ile analiz edilmesi nedeniyle aleyhinize bir sonucun ortaya çıkmasına itiraz etme, ğ)Kişisel verilerinin kanuna aykırı olarak işlenmesi sebebiyle zarara uğramanız hâlinde zararın giderilmesini talep etme hakkınız vardır.

KVKK’nın 11. maddesinde belirtilen haklarınızı kullanmak için; Başvurunuzu “Hacımimi Mah. Kemeraltı Cad. No.15 Kat 3 34424 Karaköy/ İstanbul” adresine bizzat teslim edebilir, noter kanalı ile gönderebilir veya (KEP)Kayıtlı Elektronik Posta adco@hs01.kep.tr adresine güvenli elektronik imza, mobil imza, ya da ilgili kişi tarafından veri sorumlusuna daha önce bildirilen ve veri sorumlusunun sisteminde kayıtlı bulunan elektronik posta adresiniz kanalıyla iletebilirsiniz. Talebiniz, niteliğine göre en kısa sürede ve en geç otuz gün içinde ücretsiz olarak sonuçlandırılır. İşlemin AVRASYA için ayrıca bir maliyet oluşturması halinde, Kişisel Verileri Koruma Kurulu tarafından belirlenecek tarifeye göre tarafınızdan ücret talep edilebilecektir. Talebin reddedilmesi halinde, red nedenleri veri sahibine yazılı olarak veya elektronik ortamda gerekçeleriyle bildirilir.